Updated some links, April, 2016.

The details of my 3100cc CorvAircraft engine are given below, mixed in with some details of my "interim" normal 2700cc engine.

Search this website for keywords:

I had previously planned to use a VW Type 4 for my KR2S, but heard a forum given by William Wynne on the Corvair engine at Sun N Fun in 1999. He was preaching the Corvair gospel, and it made perfect sense to me. I "saw the light", and this web page is the story of how I converted my Corvair engine for aircraft use. I don't claim to have pioneered many of these procedures, but at least I've done the research and documented how I did it. I've stretched the envelope in a few places to fit my KR2S application The bottom line is that the Corvair is certainly the most inexpensive way to get over 110 reliable HP into an airframe.

Below is my first iteration on the 130 hp 191 cid (3100cc) aircraft engine. While it wasn't legally a "basket case", most of it DID come in a blue plastic BUCKET, rusted to the max! But what do you expect for a hundred bucks? I have "thrown money" at mine, and have spent $4000 on superfluous stuff like big bore pistons and cylinders, roller rockers, racing studs, etc, and this includes prop hub and everything that it takes to make the engine run. That's just about everything new except case and heads. You couldn't DREAM of rebuilding an 0-200 for TWICE that, and you'd still be using a lot more "old" parts! But I think you could build a stock 110 hp engine with all new bearings, pistons, forged pistons, rebored stock cylinders, etc, for $2500-$3000.

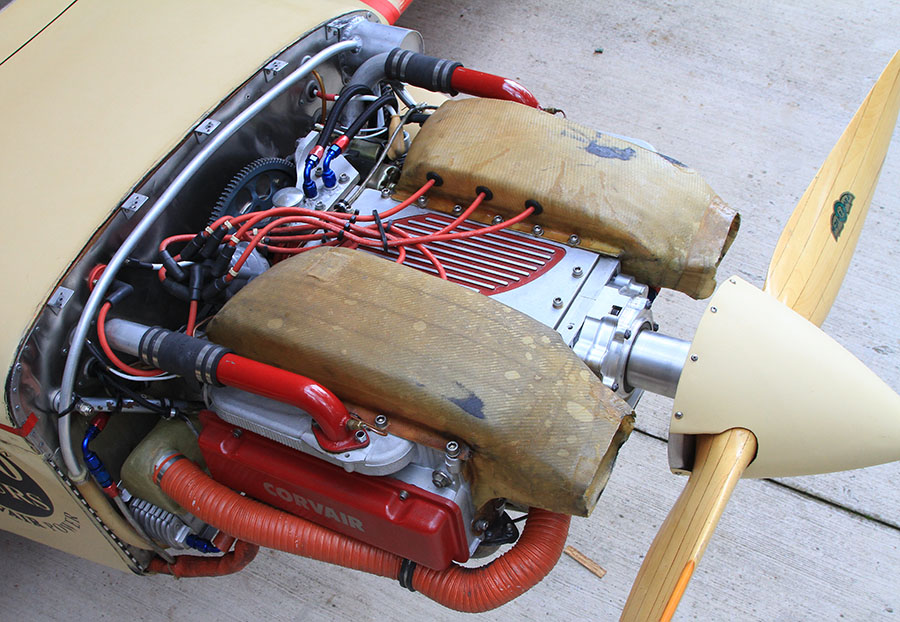

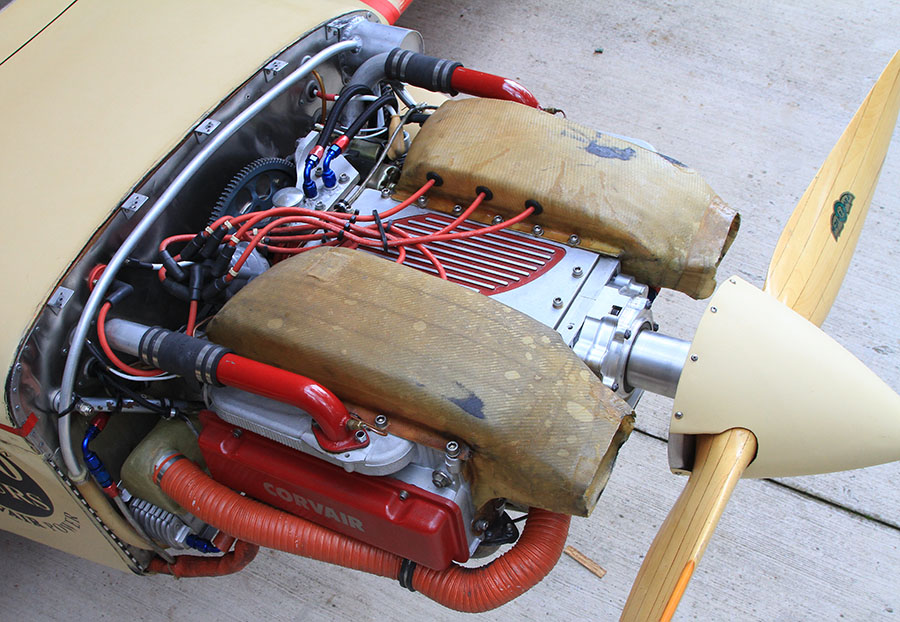

Here's what my engine looked like the day before I hauled the plane to the airport back in May of 2005. I guess mine is the only Corvair engine with "Jabiru" plenums on top, which work quite well. Head temps are reasonable, averaging 320F on a 90 degree day, with oil temp of around 220F wide open at 9500'. Many of he other "peripheral" equipment shown in this photo has evolved over the years to the photo at the top of this page, the new 3100cc "Phoenix" engine.

How did I get 130 hp (at 3600 rpm) from an engine that GM rated at 110hp @4400 rpm? Well, ditching the power-robbing blower fan helped save me 8 hp. 150 mph wind coming in the cowling does just fine. An OT-10 cam (as recommnended by William Wynne) helps, as does the Ellison EFS-3A carburetor with ram air. And most of all, a 15% increase comes from installation of the 3100cc "Mighty Mouse" big bore 94mm VW piston/cylinder set. And then there's the careful attention to detail in balancing, cc'ing the chambers for a perfect match, raising the compression ratio to 9.4:1, roller rockers, Total Seal rings, three angle valve job, minor head porting, etc.

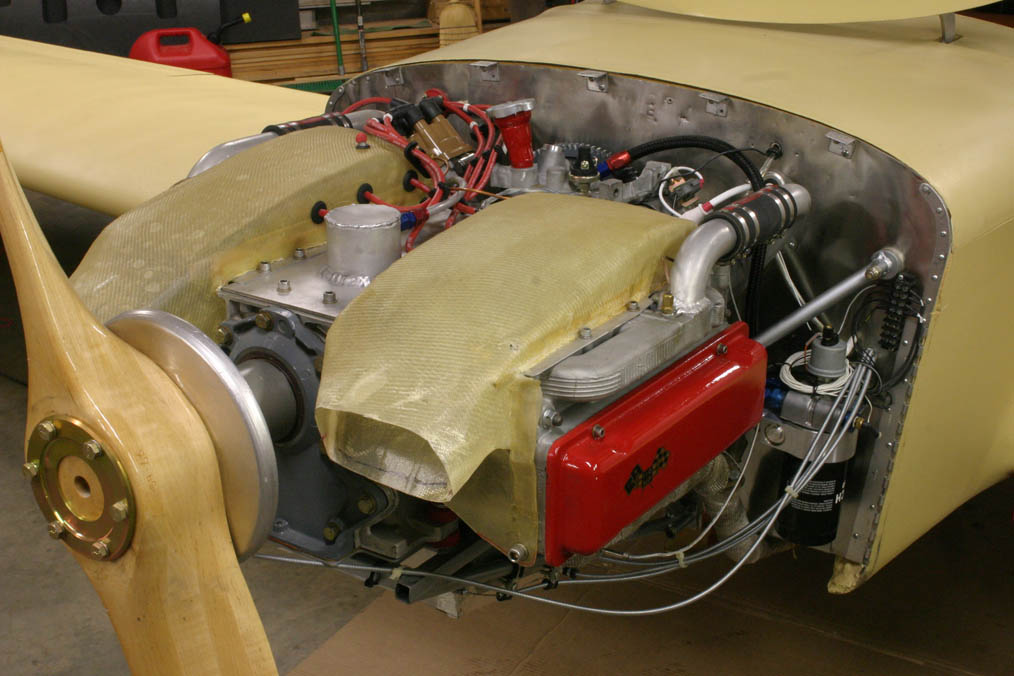

Here you can see the airbox and carb heat muff, as well as NACA duct exits. The folded fin oil cooler (available from Clarks for the princely sum of $15) is located to the left inside the fiberglass shroud. Its air comes from the passenger side engine air inlet next to the spinner.

(June 2004) Here the engine is running on the airframe and lacks only carb heat to be airworthy.

Bottom line is that it's finally finished, and it runs quite well. The rebuild procedure is excruciatingly detailed in the links below.

For assistance in building your own Corvair dream, join the "CorvAircraft" mailing list by sending a message to corvaircraft-join@mylist.com. The message list is spam and advertising free, and your email address will not be used for any other purpose.

Here's the Dyno2000 info for my engine. Please note that Dyno2000 is merely software (but good software), not an actual dyno run on this engine...

Check out these HP and torque numbers for 3500 (cruise) and 4000 rpm (takeoff). That's 130 HP and 171 lb-ft of torque at takeoff rpm and 122 HP and 183 lb-ft of torque at 3500 cruise rpm. Keep in mind that Dyno2000 predicts exactly 110 HP at 4400 rpm for the stock engine, which is what GM claimed for it in 1965, so I have a lot of faith in these numbers as well.

Here's a view of the Corvair engine, as digitized from a telephoto side view of my engine with rear starter. I then stuck the engine on a standard KR2S firewall so I could determine CG, exhaust, intake, and engine mount specifics.

The cowling shown is actually shorter than the usual RR KR cowling, and 2.5" shorter than a Revmaster. Prop clearance might become an issue, as I only have about 34.5" from crank centerline to the ground. Since I plan to run a 52" prop, that's only 9" of ground clearance, which really isn't enough for the grass strip at my father's farm that I plan to spend a lot of time on. I might also decide to use a 54" prop, and then I might just extend my lower gear brackets 2" for some "easy" ground clearance.

William sells the definitive work on converting Corvair aircraft engines for $59, which includes shipping. You'd be crazy not take advantage of his knowledge, testing, and hard-fought experience. Don't leave home without it...

Here are a few links to others' Corvair projects:

There is a FREE CorvAircraft mailing list dedicated to Corvair engine construction for use in homebuilt aircraft. You may subscribe by sending a message to www.corvaircraft.org. There are several Corvair experts and the list, and experimenters who are flying or building Corvair engines for several experimental aircraft, including one in a Dragonfly, a Tailwind, KR2s, Christavia, AirCamper, and several others. Also, the CorvAircraft Search Engine is located at http://tugantek.com/archmailv2-cvr/search. . It will help you find specific info instantly.

Return to Mark Langford's KR2S project.