The Second 3100 crank

The Second 3100 crank

January 20th, 2008

I broke another crank today, the second in my 3100cc Corvair engine. About 10 flying hours ago I developed an oil leak at the oil cover seal (which seals the harmonic balancer hub). In the interest of full disclosure, I discovered the hub had a split in it that wiped out the seal, causing the leak. I'm pretty sure the hub split because the woodruff key was either not completely seated in the keyway, and/or was forced upward when installing the balancer, because it was very difficult to install (it took a lot more torque than usual). I knew it at the time, but was too lazy to remove the rear cover and properly install the key. At no point was the balancer loose, nor was the flexplate running anything but true.

So I snagged the balancer off my 2700cc engine and installed it. It's the same one I've always flown up until the reincarnation of the 3100, with about 400 hours on it. I now have 171 hours on the "Phoenix" 3100cc engine. Up until now, this had been a very smooth engine, but after reassembly the vibration levels increased to a point that was noticeable, especially during high power steep climbs...high p-factor. I'd been altering the rpm level to avoid the rough places, and a few hundred rpm change or lowering the nose always seemed to make the vibrations a little better. I didn't (and still don't) think that the "new" balancer was any problem, since it's been used before with great results.

Because of the vibration, I was planning on having the engine/prop rebalanced again, but before I did that, I wanted the right prop on the engine. Last night I removed the spinner and front bulkhead from the plane, so I could get an honest comparison between my 54x54 Sensenich and a 54x56 Tennessee Propeller prop. I noticed that I'd accidently installed the prop off by one bolt hole...so rather than minimizing p-factor, I was maximizing it! I told my wife last night that I was pretty sure I'd solved the vibration problem, and thought I'd proved once again that indexing the prop is critical to vibration levels on a Corvair.

So today I was going to do a back-to-back propeller test between the two props, and see if I was right about the vibration during climb improving. My plan was to fly a prop at 7500 WOT, record the speed (the EIS does that for me) and then down low wide open, starting at about 2:30, and then immediately fly the other prop at about 3:30. That way the temperature would be within one degree of the other test, and all other conditions would be the same.

Another part of the test was a steep 100 mph climb to compare climb rates between the two. I started with the Sensenich, which climbs like crazy at 100 mph, and it was pretty smooth. I smiled and thought "cured that little problem". When I got to 7500' I noticed more roughness than usual, so I throttled back some to see what effect it would have. The vibration got a little worse, so I backed off some more. I kept feeling around for a smooth place, and finally realized the crank was probably broken. I thought about it for a few seconds and switched off the engine to minimize damage to the engine case, knowing I could start it back up if I needed it, just like last time. I was about 12 miles from my airport at the time.

I was already turning back toward my airport, but at that point I was so high I could have landed at either HSV, MDQ, or M38, so I glided back to my strip just so I wouldn't have to take the wings off and haul the thing back my hangar. That was a bit of a calculated risk, because my runway is only 2600' long and 40' wide, and it would be a deadstick landing, but I figured I could pull that off, given the amount of experience I have at my airport, and the fact that the GPS told me enough to know I'd arrive back there with about 2000' of altitude left. Sure enough, I made it back, but was too high for a comfortable descent, so I did a little part of the pattern, a little of the downwind, base, and then final. While on base I thought it'd be a good time to restart the engine, but it wouldn't restart! It had cooled off a lot in the 8 minute glide, to the extent that when I landed, the highest cylinder head temp was 34F degrees (OAT was 18F at 7500'). I needed a lot more primer than I was giving it during the restart, but I didn't know it, and things were starting to get a little hectic with just a few seconds remaining to landing. I didn't think it was smart to take my hand off the stick while flying that slow and low to run the primer, and the other hand was needed to run the starter. I only had two hands, so I only ran the primer for a second or two, when it needed to be continuous throughout cranking for a successful restart at those cold temperatures.

I thought I was doing fine until I got a few hundred yards from the end of the runway, then I noticed the plane dropping faster than I expected, and going slower than I'm comfortable with that close to the ground. I guess lately I've been carrying a little power all the way down to the landing, because I've been doing more of a wheel landing than three pointer. So this time I sold myself a little short and realized that it was going to need some power, but didn't have it. I could have raised the flaps, but then I'd have been flirting with a stall. So I landed about 20 yards from the end of the runway in a plowed cottonfield. Maybe I should have said "started landing", because at 60 mph, 20 yards goes by pretty fast, and I coasted halfway down the runway. At that point I was curious as to whether it would start, so I gave it a few seconds of primer and it fired right up. I switched it off and pulled it to the hangar. The only real damage was to one wheel pant, although the fairings between the wing and the gear legs got another good stretching on them, and a few errant cotton plants got uprooted and dragged out onto the runway. Still, it beats a stall/spin from 300 feet anytime. I was quite surpised that it wasn't a lot worse.

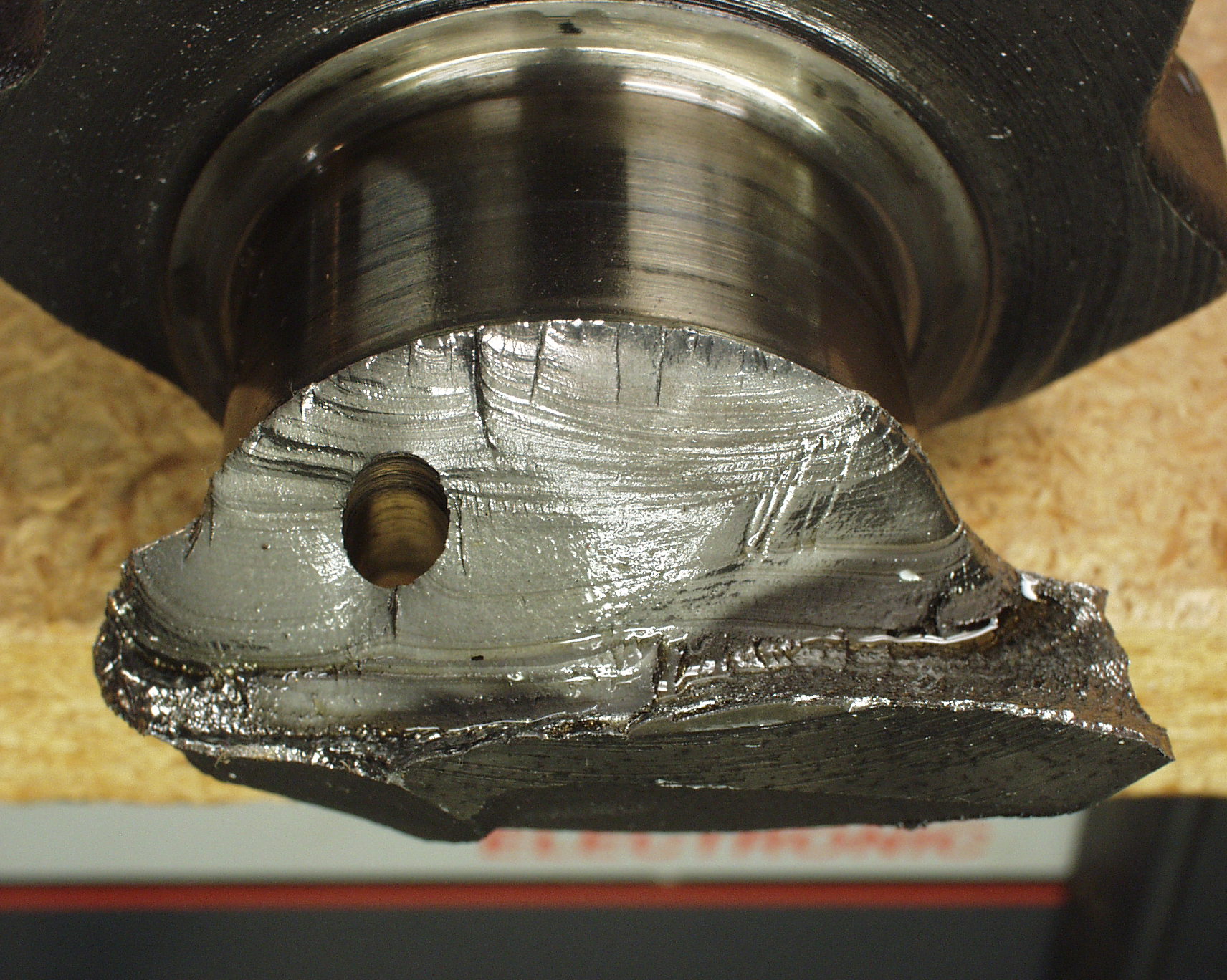

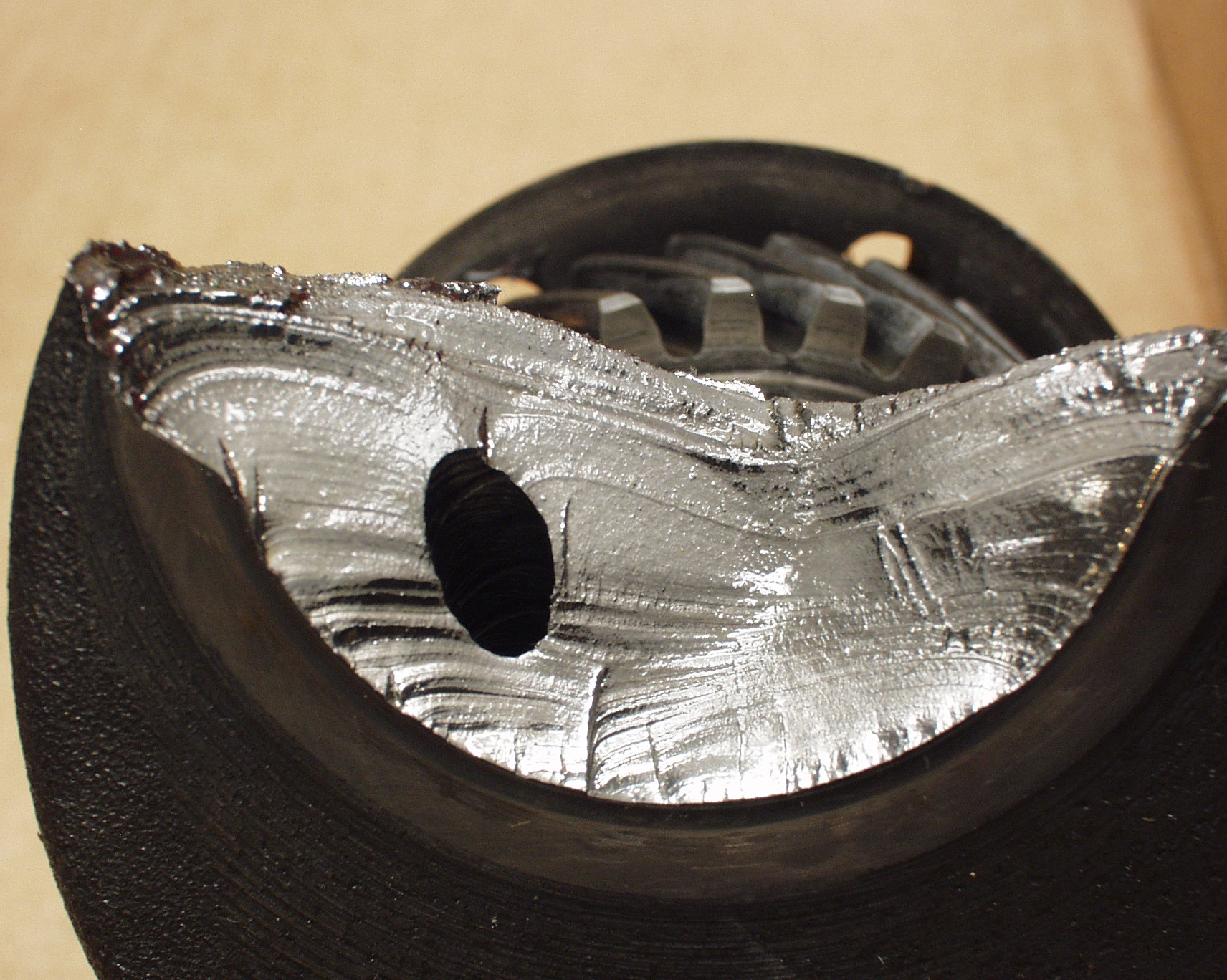

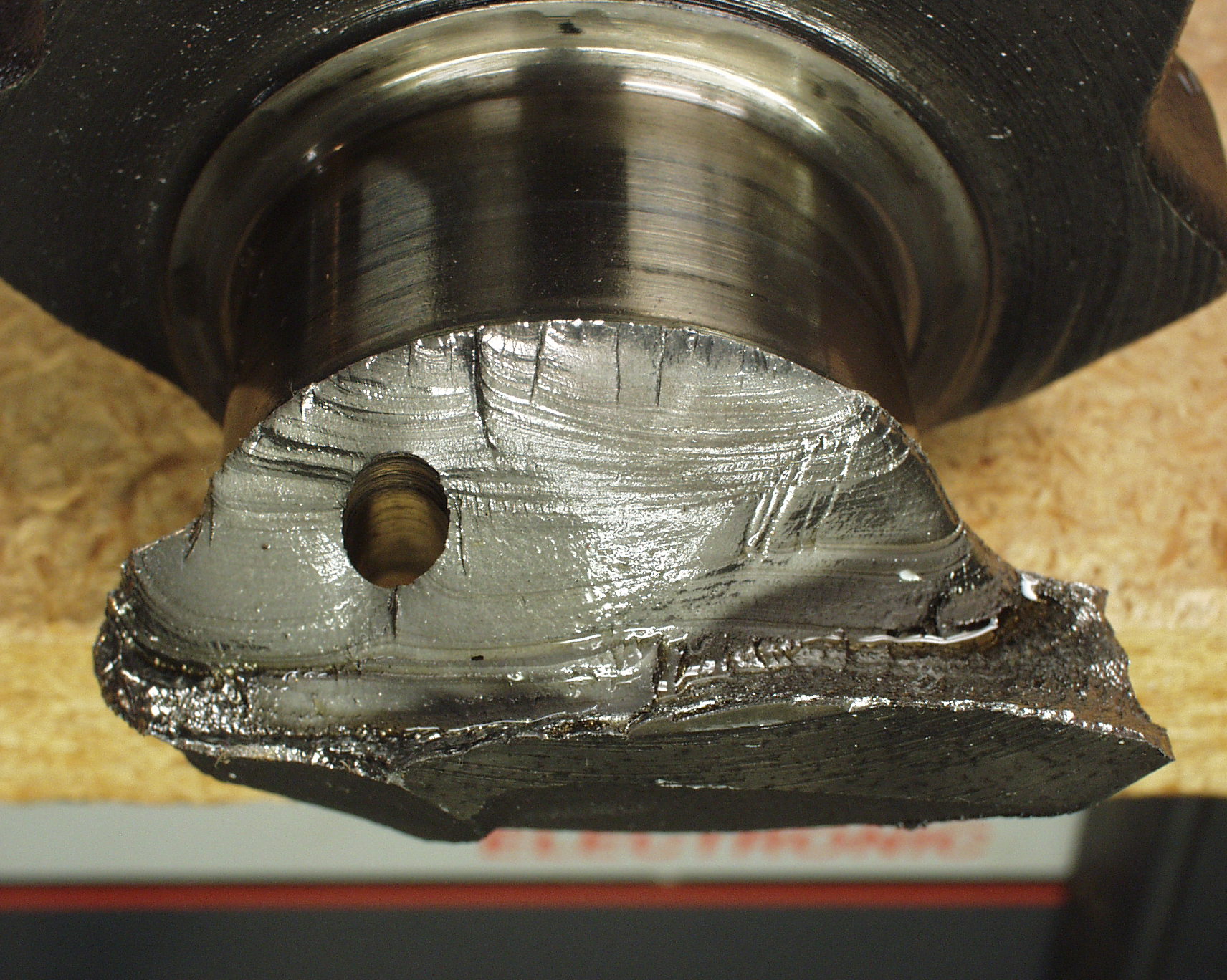

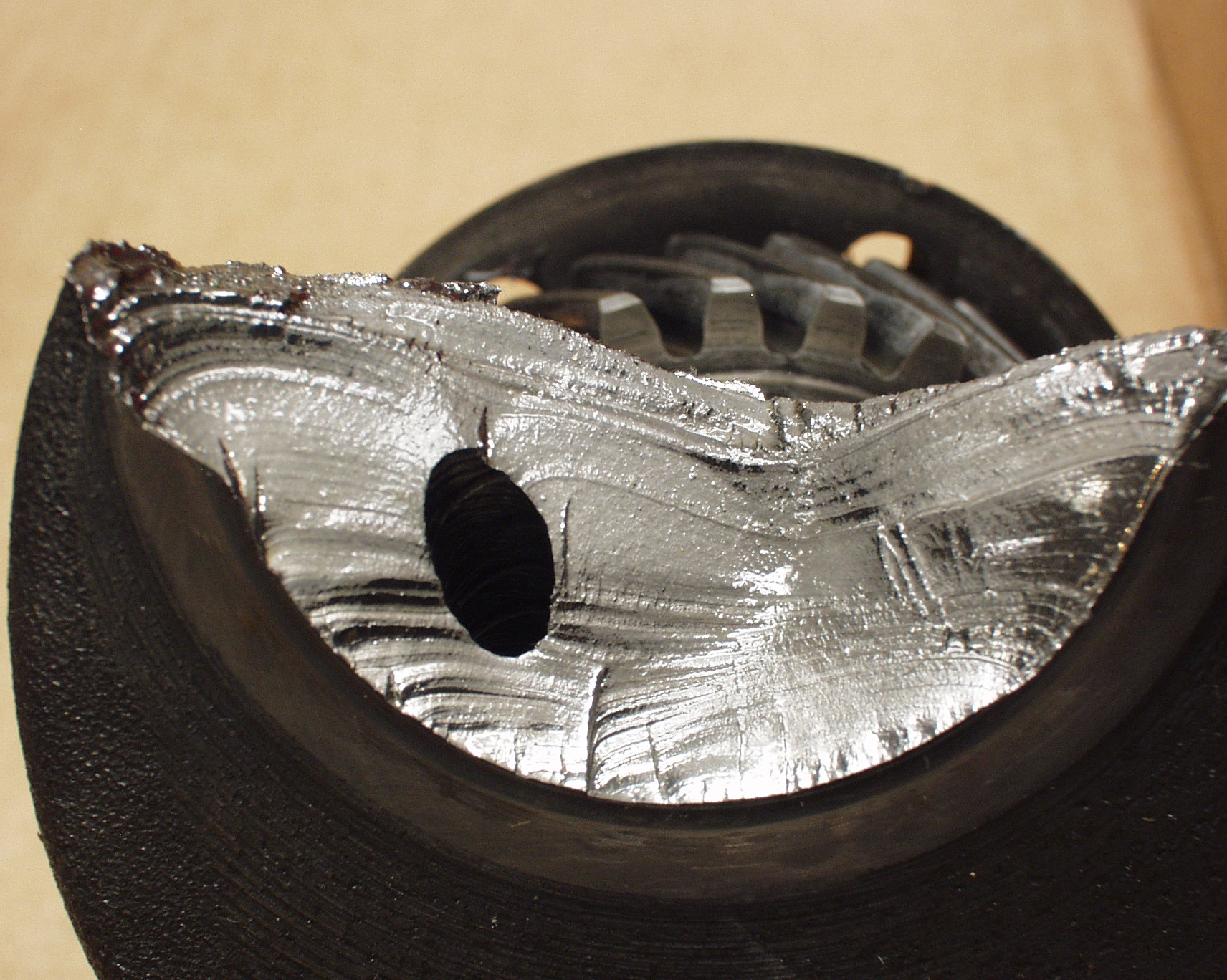

Sure enough, the prop tips wiggled back and forth about 3/4", and the prophub was still firmly attached to the end of the crank, with safety shaft nut still tight. I didn't bother disaasembling it, but judging by the range of motion, I'm pretty sure the break is right where it was last time, between the number 6 crank journal and the main.

I'll confess that on the ride home I thought about the possibility of an 0-200, but for the moment I'm thinking of designing a front bearing to take the propeller loads for the 3100. Maybe I'm stupid, but it's another challenge that can't go unanswered. I'd already given it a lot of thought back when I was going to use a Type 4, so I'll take another look at it with respect to the Corvair.

For the moment, the 2700cc engine is going back in the plane. I need to swap a few little parts around from the 3100, but it should be back in the air in a week or two.

Again, I only post this for full disclosure. I don't want somebody accusing me of hiding my crank break. I know I was a little irrate when my first crank broke and I found out that a couple of other CorvAircraft member's cranks had broken in the previous few weeks and months, but had not notified the CorvAircraft list.

Update, Feb 26, 2008

This picture looks almost identical to the failure mode seen in my first crank break...several simultaneous failure points marked by ratchet marks. This failure clearly originated at the radius of the number 6 cylinder (at the top of the picture) and slowly marched downward toward the forward main (towards the prop).

Anybody that tells me that the oil hole was the origination point doesn't understand what they're seeing, so please don't say that out loud. The oil hole was just caught up in the meelee...

Return to www.N56ML.com.