Mark Langford's KR2S Project

Corvair inlet plenum

created Nov 5, 2003

updated June, 2016 - added an update clarifying that plenums do indeed work, and countering an "alternate opinion" from TCA.

The Corvair engine has a very convenient means of connecting an intake plenum to the case and heads. Two flat surfaces on either side make it a simple matter to fasten two aluminum angles. I cut out two cardboard templates and trimmed them until the cowling fit snugly, and then cut some Home Depot Styrofoam to rough shape and installed it between the cardboard. This photo was taken after sanding to shape.

I covered the whole thing with duct tape as a mold release and to smooth out the rough spots.

I used the time-honored plastic sheet method to layout the exact shape that I'd need the fiberglass cut to...

... and laid up two pieces of 9 ounce cloth, wet out with AeroPoxy.

This makes it easy to put the glass where you want it, and ensures that the layup doesn't turn into a long skinny mess between the table and the target.

A little smoothing and it looks great.

A little coaxing and the plenum was removed and cleaned up. There's still a little more to do, but this is essentially done. It took me about three hours total to do the first one, and I'd expect the second one to take about two hours.

Here's the view the air will get just before it's forced down between those hot fins! The back side of the plenums extend down and tuck in under the lower cooling tin. I did this by extending the duct tape from the foam down over the cooling tin, and then after curing, I simply tucked it inside the tin, rather than the outside. It doesn't get much tighter or more effective than this.

Spark plug wires were run through rubber grommets each plenum's inside, but another option is overlapping phenolic or other non-conductive material, with screws securing the halves together. This way the plug wires are easily removed. It never bothered me that they were captive in the grommets though, not enough to do it any differently.

I think the plenum concept will work very nicely with my NACA duct setup evacuating the underside of the engine. I'll pull the oil cooler air off the backside of the passenger plenum, since it will gather more air due to the shape of the inlets. Intuition would tell you that the epoxy will soften and this plenum scheme won't work, but it's becoming common practice on many homebuilts.

UPDATE June 2016

I've put 1130 hours on these plenums, and never had a problem of any kind with them. Other than some darkening over the years, they look exactly the same. Concerns of the heads or cylinders deforming them were unfounded, despite the low Tg (softening temperature) of the Aeropoxy I used with the fiberglass. I never painted them because I always had some flying to do first, and because I'm a deadbeat.

Why don't they melt? During flight, under-cowling temps (measured at the top of the firewall) are maybe 20 degrees warmer than ambient. Things do get toasty after parking on a hot day, but there are no loads on the fiberglass, so it doesn't deform.

On my next set, I'll use the aluminum angles for initial construction, but only as a mold to create the mounting surfaces of the plenums (using duct tape as a release agent). This is so easy, I don't understand why plenums are still rare, even in the experimental aircraft world, and especially on Corvairs, where they are so easy to make.

In 2009 I measured the pressure differential between plenums and below the engine, and had a solid 8" of water differential, which is better than any number I've seen for a baffled cowling (most report the best you can hope for is 6-7). This is a real increase in cooling potential. Since I took these measurements with the probes immediately above and below the cylinders, I now know that the real number of total differential is significantly higher when measured in the more typical location of within the plenum and near the cowling exit.

To remove the possibility of ram (dynamic) air influence, I made these probe tips as replicas of my static port tubes.

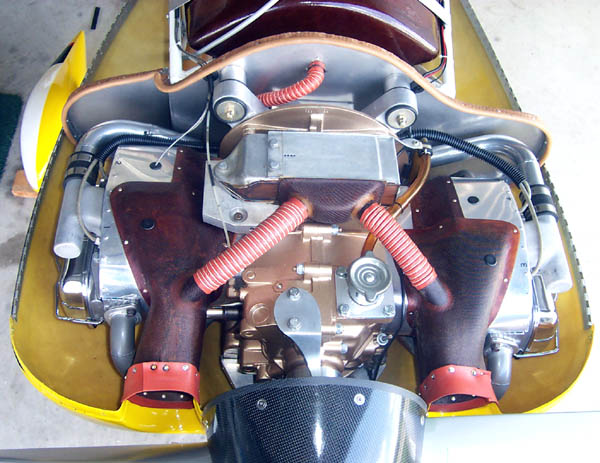

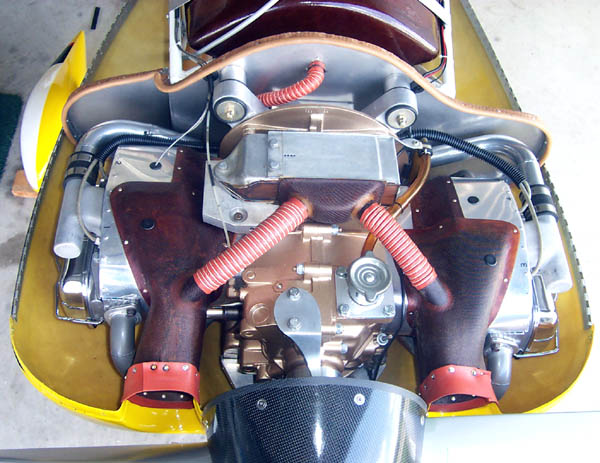

Here's another plenum implementation, which I believe is Bill Clapp's (judging by the paint job). Clearly, he tried harder to make his look nice. Again, super easy to make these for a Corvair.

This is a gorgeous VW Type 1 plenum on a Sonerai that Steve Bennett sent me. It's one of the finest (and few) I've seen on a VW. It's work that's worthy of copying. But I'd do it all in fiberglass...it'd be a lot easier than trying to bend aluminum into compound curves!

Here's another fiberglass VW plenum, and it's just plain incredible workmanship! I forget whose this is, so please claim it so I can give you credit.

Pretty awesome piece.

As you can see, putting a plenum on a VW is considerably more complex than a Corvair, which is the ultimate in simplicity. This plenum is an inspiration...

Recently I've heard from two different guys, one of which is a KR pilot, that WW says plenums will make your engine run hotter, rather than cooler. I found this hard to believe, so I looked up "plenum" using the search box at the top of www.flycorvair.net, and after several paragraphs of how Mark Langford's 3100cc engine wasn't really working very hard, I found this:

"The KR climbs at a much higher airspeed and requires less power to fly at any airspeed over 120mph (than a Panther). In short, It’s engine is not working nearly as hard... Here are two examples why this matters: Frequently builders say to me “I want to use fiberglass plenum cooling on my plane because it worked on Mark's plane, and it was the most powerful Corvair”. This is a false conclusion. If you put Mark's cooling ducts on the Panther and flew it the way Dan does, it would overheat. The ducts work on a KR because of it’s higher airspeeds and the fact the plane can not be flown as aggressively or under high loads. A KR builder could use ducts, but we also make a standard Cowl and JSWeseman.com has a baffle kit for it. It is the same type of cooling as the Panther and the Cleanex have."

This makes no sense to me. By definition, plenums are essentially very tight baffling that forces ALL of the air that comes through the inlets over a head fin or cylinder fin before it exits, and does so in a more aerodynamically efficient manner through "smooth design". How does speed even enter the conversation? Sure, speed is a factor in cooling, but the choice is simply between a baffling system with feet of air gaps, gap around the spinner, and potentially leaky silicone seals, or a plenum that forces all air over a fin. How is it possible that baffling could cool better than a plenum, given ANY particular speed or high heat load? It's NOT possible, and it has been proven, and it's just common sense that it would be better.

And then there's the obvious benefit of decreased cooling drag. Less air required means lower drag and higher speed, which equates to even better cooling, for a given power setting.

I got the plenum idea from the Jabiru, and Troy Petteway probably did too. He put a plenum on on his KR2 back when it had a VW engine, and reported a dramatic drop in CHTs afterwards. That was all I needed to make my own plenums when I finished up my Corvair.

Back when Joe Horton finished up his plane and had his engine broken in, we flew to Beckley W. VA (the halfway point between us) to meet each other and check out each other's planes. Our engines are identical 3100cc engines, down to the location of the CHT probes and the EIS data engine data readout. When we took off for home, we took off together and during climbout each of us called out our CHTs. Mine were about 50F cooler than Joe's, all else being equal. One could argue that Joe's oil cooler is within the baffling and siphons off some air, and I'd say "that's another reason why the plenum works better". My cooler is mounted to the firewall, and fed by a separate duct. But even a cooler mounted in the stock location would benefit from being fed by a plenum, rather than baffling.

Later, at the November 2008 Corvair College in S.C, we did a pressure test on both planes with a manometer. The pressure difference was definitely higher in my plenum than with Joe's baffling, although I can't locate exact numbers at the moment. That was good enough proof for me and Joe that the plenum was a plus, not that we needed it.

In the case of the Type 1 VW, another advantage of a plenum is the ability to dodge those hot exhaust pipes right at the cowling inlets. These hot pipes raise cooling air temperature before it even gets to the cylinders or heads. I will eventually replace the baffles on 1JF with plenums, and will make a point of measuring pressure and CHTs before and after. I believe in testing, data acquisition, and accurate reporting of the results, and I encourage others to do the same. It's up to individual builders to weigh the facts, and decide what makes sense and what doesn't, but I have confidence in you!

What possible reason could WW have for this viewpoint? Given that a guy can build a pair of plenums in an afternoon for under $10, and have significantly cooler temperatures, I leave it to the reader to figure out. It's beyond me, unless it's a lost revenue concern.

There's another plenum "red herring" at

Flycorvair.com, second picture down, where WW follows this same train of thought, and points to a very bad inlet design and says it was inspired by my plenums, which are "most similar to cooling plenums like the ones seen on Mark Langford's KR-2". Uh, I think not. See below for the photo that he's talking about. Looks just like my plenums, doesn't it? Scroll up and take a look. Yeah....

It seems WW never misses the opportunity to bash plenums or the rear starter, both of which have been demonstrated to work fine, and I've shown how to do easily and inexpensively. Starters and permanent magnet generators need no extra cooling, so why put them out front? Some installations may require it, but if they'll fit on the back end of the engine, why not? And if they'll fit fine in a KR installation (which was originally designed around the VW), they will fit on many other aircraft.

For some interesting info on the design, testing, and installation of Jabiru cooling plenums see

Jabiru Cooling Plenum installation manual.

Return to Mark Langford's KR2S Corvair Engine