updated May 7, 2006 (added new photo at the top).

July 2004...It's done! Here's a picture of Troy doing 200 knots straight and level about 6 feet off the runway in his KR2. Notice how his elevator is in perfect alignment with his horizontal stabilizer. That's when you know you've got it right! He's been fine tuning and tweaking the aerodynamic stuff and the engine, and recently painted it. Notice how nicely everything on the this plane is faired, such as the engine air inlet and exhaust system. Tailwheel fairing is done, but not installed yet.

He's redone his seat to a carbon fiber affair, and swapped the single stick for dual sticks.

His wings are the AS5046 with the regular KR2 planform and length, but with only 1 degree of incidence at the root and zero at the tip (1 degree of washout). His horizontal stabilizer is at the stock angle of zero with respect to the fuselage, mainly because he didn't want to tear it out and redo it when he built the wings. The wing rebuilding happened after an engine-out landing on a farm road that went sour after a tractor pulled out in front of him at an inopportune time during rollout. He can do 200 knots flatout straight and level. It stalls at 50 knots power off and 45 power on, with no wing drop. The tail shakes a little for the stall warning, and Troy says you get plenty of notice.

While he was re-doing the wings, he extended the horizontal stabilizer 6" on each side, while also removing about 4" from each side of the elevator (which went to the horizontal stabilizer also). He says pitch sensitivity and stability is MUCH improved now (and yes, that's with CG range the same before and after). He also cut his rudder down a little, just to match the elevator, and it's still enough for the C-85's torque.

The AS5046 requires gap seals if you build the ailerons using the same method as the RR plans call for on the RAF48 because of the huge gap. Without them climb is marginal. These seals have lasted for years just fine, and were replaced only to repaint the wings.

Empty weight is 620 pounds. The prop is a Sterba 59x74 that he spins up to 3300 rpm flat out. He'll be the first to tell you that he needs more pitch.

It's ready for the KR Gathering now, and he says he'll be there...

Well, it flies great and the testing is pretty much done. Today we added gap seals to Troy's ailerons. It took maybe 15 minutes, start to finish, and then he flew it. What brought this on? Troy noticed that during takeoff at high incidences, the plane really didn't like to climb at all. Although he IS 90 pounds heavier with the new C-85 engine, he also has more power. With the new Sterba prop he's developing 2500 rpm static, and has wound it up to 3100 rpm at 175 knots wide open (!!!!!!), straight and level. That would be the magic 200 mph, folks! Anyway, his theory was that the aileron gap was being "exposed" at high incidences and was inducing a lot of drag. It seems he was right.

Here's where I'm talking about. Not hard to see that there might be a problem here...

The gap seal material was something that Oscar Zuniga dug up for me a few months ago. I think he needed a guinea pig, and I'd say he's found a very happy one already. It's 10 mil thick Mylar, and is fastened on with some double sided 3M Scotch tape that Oscar also kindly provided. I'll get details later, but it's the ticket! You can also see his balance weight here, which is something you don't usually get a good look at. Keep in mind that Troy hasn't painted his plane yet.

Here you can see the strips of Mylar, 2" tall, and fastened with the 3M tape. Just for good measure, he also covered the forward edge with a line of electrical tape. He'll leave this in place until he paints the wing, and will then replace it with a piece of white tape. Notice how nicely this stuff covers the gap. Bottom line on this stuff is that it made a very large difference in the climb ability of the plane at low speed and high incidences (from around 500 fpm to almost 1000 fpm). Higher speeds were unaffected, as were stall speeds. The ailerons were also lightened up, which would get them in closer harmony with the elevator. All in all, A BIG IMPROVEMENT!

Troy credits his extended horizontal stabilizer as one of the contributing factors for his improved pitch stabliity. He says the shortened elevator (back to the edge of the outer hinge) helps in the sensitivity department.

These wheel pants are from Klaus Savier. $230 or so, but they sure look fast! And they're light, as well.

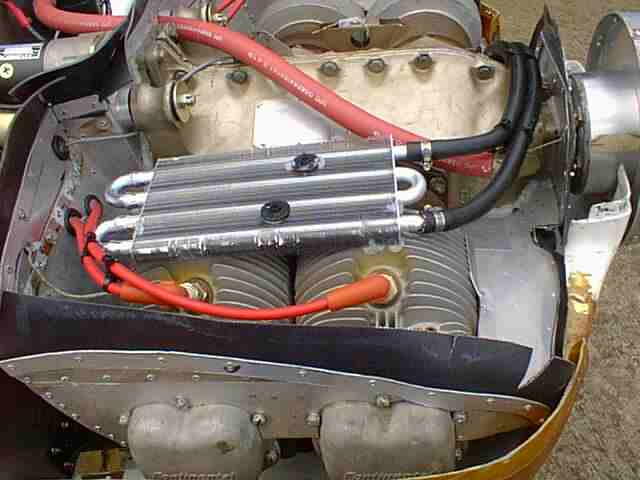

This is a trial oil cooler which reduced temps 25 degrees, but makes the rear cylinder run a little warmer than the rest.

I suggested the Corvair version, which William Wynne welds AN fittings onto. He promptly took it home and mounted it to the baffling at the rear of the pressure cowl. We'll see tomorrow how it works. This is probably a significant improvement over the tube and fin version.

Here's how much your Revmaster cowling has to be cut back for the C-85.

Interior is next, but I wouldn't complain, myself.

Here's the pickup for the electronic ignition (which includes and advance and knock sensor). It's mounted to the back of the spinner.

Hey, the tailwheel's not even faired in yet! This is a rollerblade wheel, designed especially for asphalt.

What a day. I learned a lot from Troy and his plane in a few short hours. And now he climbs out a little faster. Back to Columbia...

Jan 19, 1999 - New wings

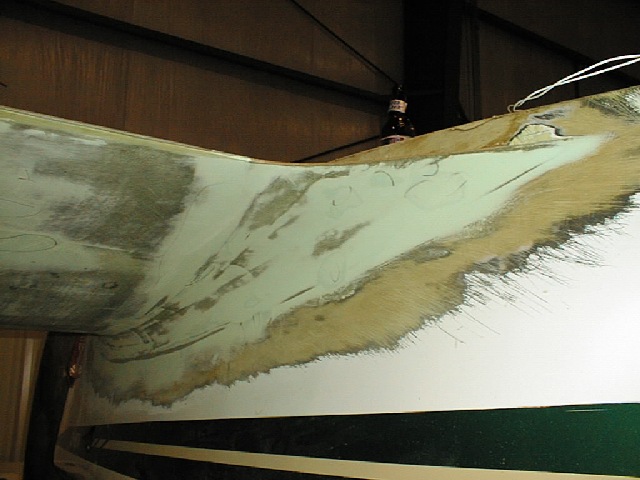

Troy had a little "incident" in 1998 while flying near a local river in a heavily wooded area. His carburetor quit and since he had no starter he had no way of getting it restarted. The resulting forced landing on a farm road left one gear leg bent beyond repair, both wings damaged, and the bottom of the cowling and carburetor damaged. Below is the reconstruction. This happened just as the AS5046 airfoil was designed, so he jumped on the opportunity to use it.

Nathan and John preparing the foam with EZPoxy.

Troy has just applied the second layer of glass.

Wing root fillet.

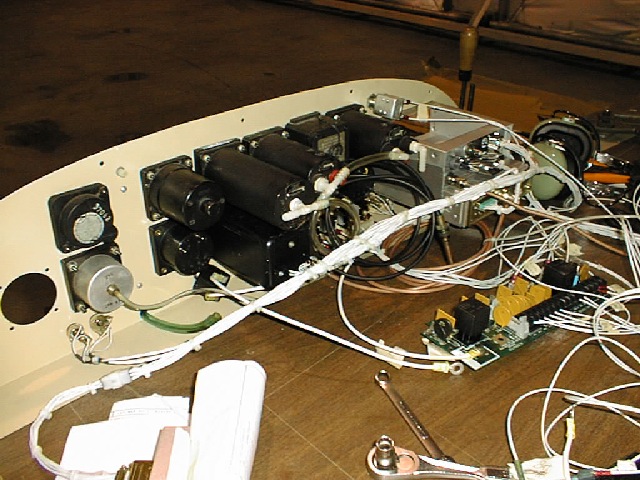

Troy built a new panel to house his new Bendix King radio and GPS. He tested it on the bench, with all systems plugged in and working, including the fuel pump.

Pretty sanitary looking from here.

orking the epoxy into the glass along the leading edge.

He used an aluminum angle along the trailing edge to keep it straight. The jack underneath maintains washout during the process.

Troy's epoxy warming cabinet. He says it really helps when wetting out glass.

Troy's gear legs, made from Aluminum bar stock, similar to a Grumman. Grove aircraft sells a similar setup for $500 at www.groveaircraft.com.

Rollamatic installed. Note rolled aluminum at bottom of firewall to smooth exiting air into duct on plane's bottom. This is a trick outlined in Paser's book "Speed with Economy".

Lengthened horizontal stab, done in carbon fiber, as well as new taller vertical stab.

RV servo installation. He says it works great thru a switch on the stick, and is dirt cheap. More on this later.

Like Mims, he's making his wing joint permanent. If he ever needs to remove his wings, he'll bring his saw. Until then, it's very smooth looking.

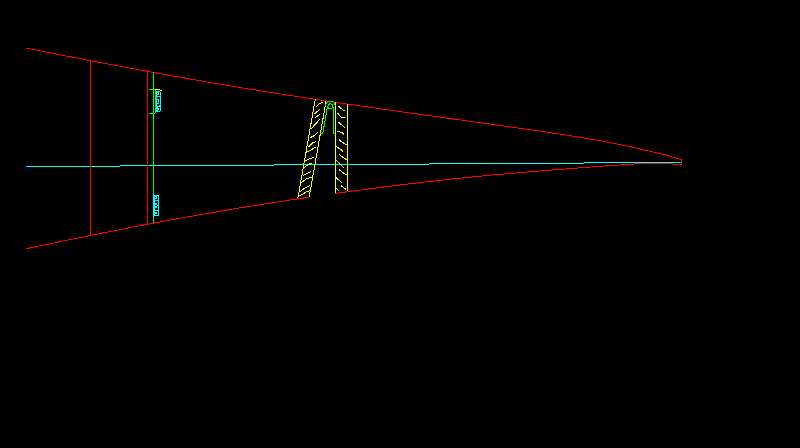

Troy's using the AS5046 airfoil, with a stock KR2S planform.

The King Air in the background is where Troy usually works.

He now has over 80 hours on the new wing and loves it! Here Troy lacks only some finishing work on the cowling and a paint job before he's done. He took both of my kids for a ride and they were thoroughly impressed!

This cowling is what has to happen to a Revmaster cowling when

you stuff a C-85 under it. These were all taken upside down and rotated

later on the computer, since I had to frame and shoot them with my left

hand. Troy swears by his smaller elevator, saying that he still has plenty

of authority when landing and rotating out. He also reiterated that it

slows down more quickly when landing (in ground effect) due to increased

drag on the new wing at high incidences, and climbout is now at a more

comfortable 100k. Liftoff is at about the same distance as before (even

though he's 90 pounds heavier now), but he now runs it up to 100k to climb

out rather than 80 as he did with the RAF48. He likes the climb out at the

higher speed since it also increases cooling.

The results were simliar even when he still had the VW but was using the new airfoil. Top speed is the big difference with the increase in power he gets from the C-85. As mentioned before, his power off stall speed has gone from 47k with the RAF48 to 49k with the AS5046, which makes sense considering his airplane's gained 90 pounds since then. A little paint and she'll be good as new...

To learn more, visit

Return to the earlier VW powered days of N100TP.

Return to KRNnet