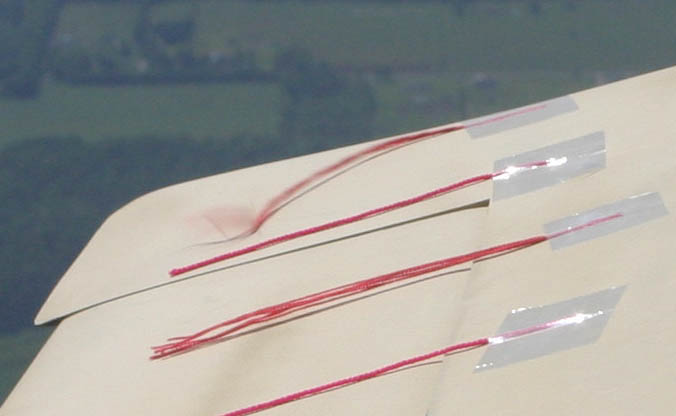

Here's what the propwash is doing at idle. The engine is a Corvair and is rotating counterclockwise as viewed by the pilot, so this is not unexpected.

created April 12, 2006

Here's what the propwash is doing at idle. The engine is a Corvair and is rotating counterclockwise as viewed by the pilot, so this is not unexpected.

At high speed, things look pretty normal, with flow appearing to be attached over most of the surface. There is some detached flow at the aileron, which tells me that gap seals will improve things. You can also see that at the trailing edge out on the tip, flow is bending inward, so the wingtip needs some work.

This is during a high rpm slow speed climb. Flow is detached at the wingtip.

I forget exactly what I was doing that caused this. This tufting exercise was really just to get my feet wet, with no real recording of what was happening when each photo was taken. I'll do that later. One thing I learned immediately is that nylon string is useless for these tests, as shown by the two purple-ish strings that are second and fourth from the tip. The yarn does a much better job of showing what's going on. I'd have thought yarn would have self destructedin a matter of minutes, but it works fine. I'll rig up a video camera for future flights, and keep better records.

This is just plain old yarn with some clear packing tape holding it in place. It probably took me 3 minutes to install all of these (although I should have put on a lot more), and a minute to rip 'em off. Some of you guys with Diehl or other different wingtips are welcome to try this and let me know what you find.

Return to Mark Langford's KR2S Time Machine