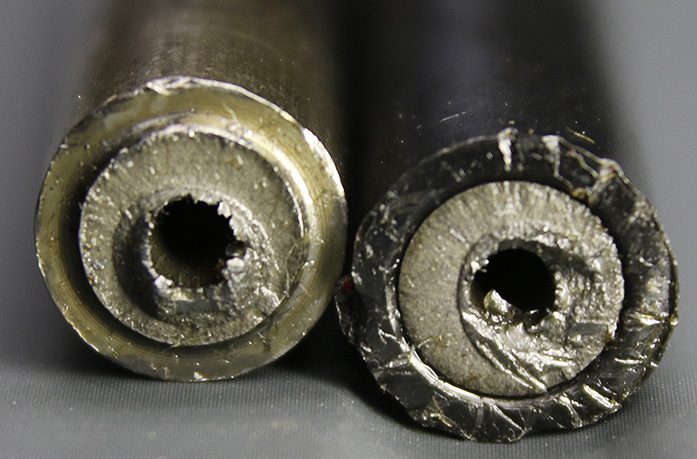

Here's a closeup of the mating surfaces of the pushrod, revealing an internal pin that was used to join the two pieces before the break. Given that he built a 3100cc engine, I assume this is a custom pushrod that is longer than stock.

created July 12, 2020

Ernest Christley recently posted on the CorvAircraft list that he had broken a pushrod, after cruising smoothly steady-state for 20 minutes before the engine became a five-cylinder. This pushrod only had about 80 hours on it. He posted a photo of the broken ends to the CorvAircraft list for ideas as to what may have caused it, and I requested that he mail the pushrod parts to me so I could do a little "failure analysis" on it.

Here's a closeup of the mating surfaces of the pushrod, revealing an internal pin that was used to join the two pieces before the break. Given that he built a 3100cc engine, I assume this is a custom pushrod that is longer than stock.

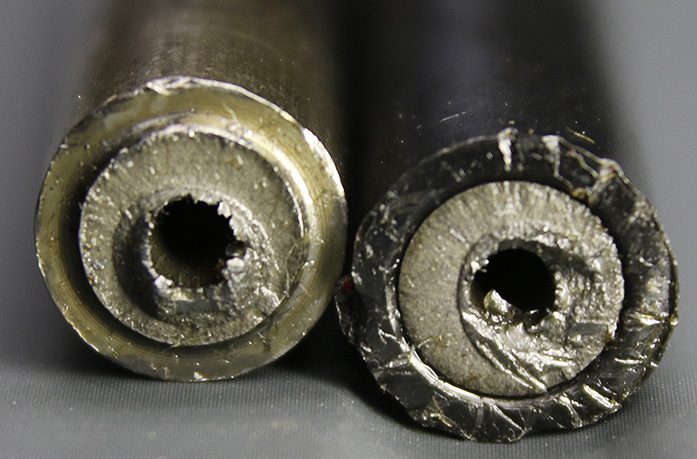

The photo above shows the broken one, second one down from the top. Clearly, this thing is made out of two different parts. The left side appears to be a stock Corvair pushrod, while the right end is an aftermarket tube and end. The two pieces are joined by a steel dowel with an interference fit, and a hole drilled through the middle for oil passage. I sectioned a factory pushrod, and it has an internal diameter of about .214".

The two pieces are not welded together, probably because welding neutralizes the heat treatment of both parts, making them weaker, and would likely distort the pushrod length into a bent shape anyway. This assembly leaves a central dowel of smaller diameter than the tubing would have if it were continuous, which essentially creates a part with a 360 degree "stress riser" around the circumference of the pushrod, weakening it significantly to any kind of bending forces, which could (and apparently did) cause the center dowel to fail. The likelihood of a failure would be even higher if the two pushrod halves were not pressed all the way to close up the gap between the two parts, leaving more wiggle room between the two to increase fatigue. Close examination of the dowel shows a fatigue failure that eventually failed off to one side, leaving what appeared to be a bent pushrod. There may be other factors at play, such as the "dimple depth" of the lifters themselves, with deeper better than shallow.

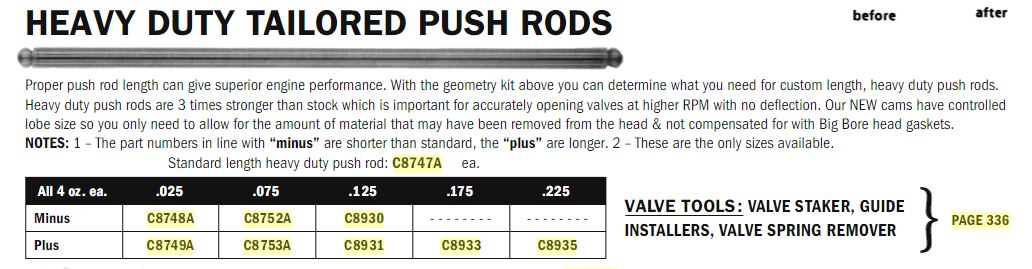

Back to this photo, the pushrod at the top is a similar (but with different opposite ends) "unbroken" pushrod like Ernest's, but this one came out of MY engine. The third pushrod down is a stock Corvair pushrod, which has no joints, and no ends pressed in....it's made in a more complex way to give the ends the proper shapes, without adding any stress risers. The fourth one down is an OTTO Parts aftermarket pushrod, and the bottom one looks like a stock pushrod with a compromised surface finish. There's another variety shown in the Clark's Corvair catalog, which is also a custom pushrod with several shorter and longer lengths for engines like mine and Ernest's, which have machined heads and other changes that need non-stock pushrod lengths to maintain proper valve train geometry. See below:

This is from the Clark's Corvair online catalog, and according to the catalog, is "three times stronger than stock", and certainly it would be more resistant to bending fatigue issues, regardless of the underlying cause of the bending (rocker arm, geometry, adjustment, etc). And the stock pushrod has a proven track record as well, if stock length rods fit your engine.

According to my Valve Train Geometry page, I ordered my pushrods from Ray Sedman at "American Pi", which I have 550 hours on in the 3100cc engine, with no problems at all. I also feel like there is some other issue at play in Ernest's engine that is causing these kinds of pushrod problems. There was a slot cut into the associated rocker, and initial valve adjustment is suspect as well.Still ensuring that valve train geometry is optimized is just good practice, and can minimize valve tip wear and guide friction. See my 3100cc Corvair Valve Train Geometry webpage for more on how I ensured the valve train geometry was optimized.

Return to Mark Langford's KR2S Corvair