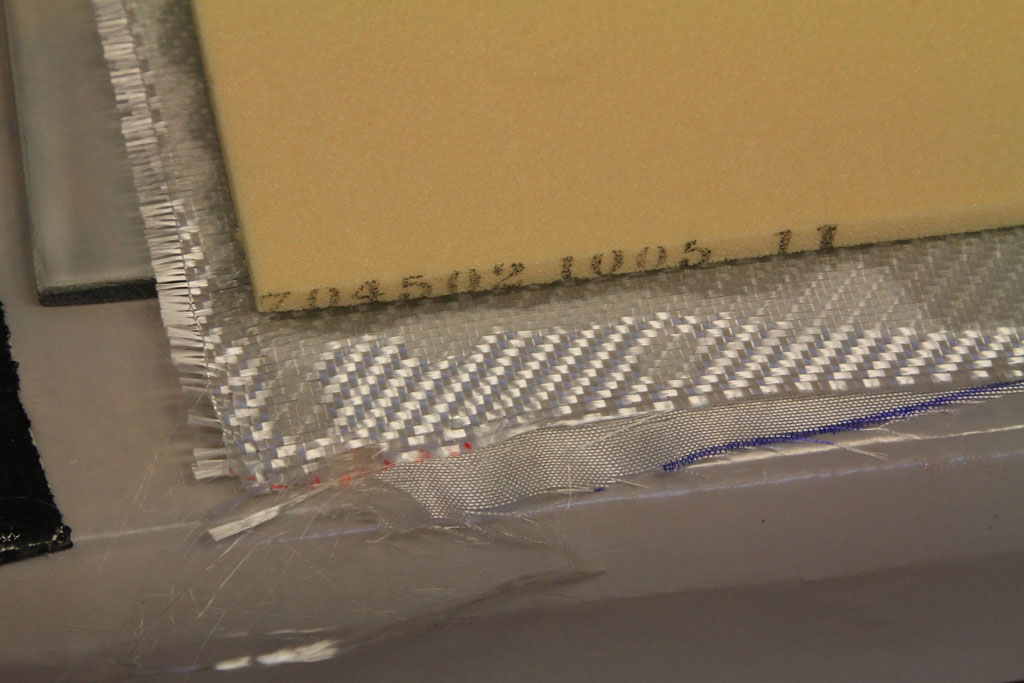

The first step was to make some "plyfoam" out of glass and 1/4" Lastafoam. This is the inner and outer layup...one layer of 9 ounce fiberglass covered with a layer of deck cloth.

This year Jeff Lange finally managed to talk me into signing up to run the Airventure Cup Race, scheduled to run from South Dakota to a small airport near OSH. I was going to need more fuel to make the trip non-stop, so I built an 8 gallon wing tank. Vinylester was used for everything, because it was designed to be resistant to ethanol and autofuel.

The first step was to make some "plyfoam" out of glass and 1/4" Lastafoam. This is the inner and outer layup...one layer of 9 ounce fiberglass covered with a layer of deck cloth.

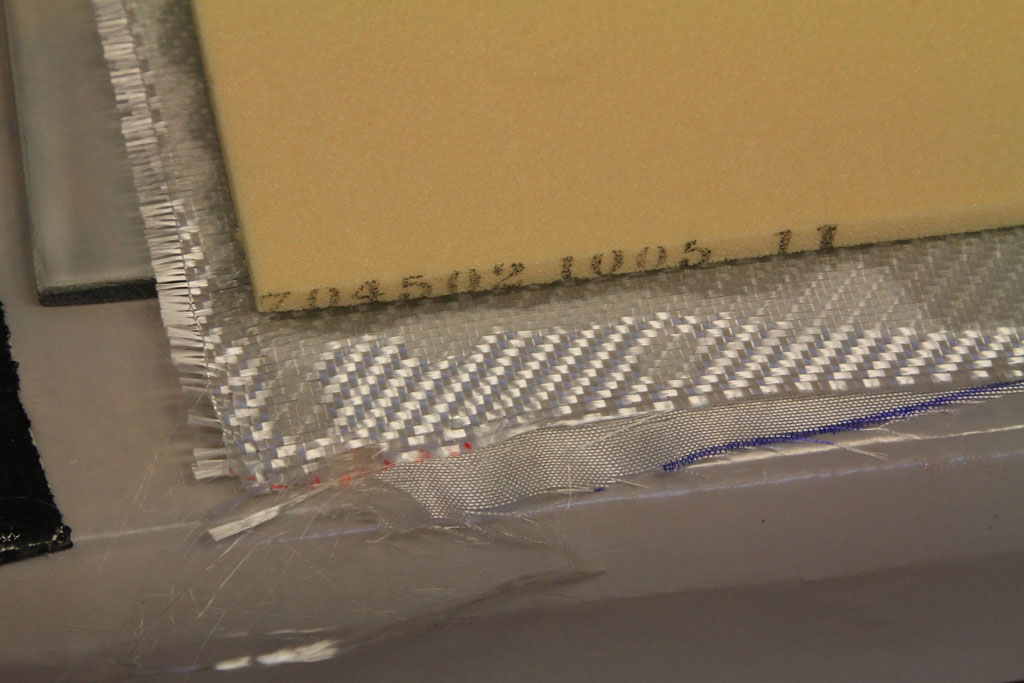

I made several panels, corresponding to the desired dimensions, plus some for trimming. In this photo, I was creating ledges for the top and bottom, using a duct-taped (as a release) aluminum angle, and glass/micro fillets to reinforce the joints.

After quickly roughing up the edges with a pad sander to ensure good joints, I joined the panels together with micro corners and two layers of fiberglass tape, one 1" and another 2", smoothed into the micro microfillet soon after it was spread. I was not stingy with the vinylester...I don't want any leaks. I got this far the first day, because vinylester sets really quick, especially in the summer in Alabama. One day it was 108 degrees in the hangar. If you're wondering what this photo is all about, I was siphoning out the fuel that I left sitting in it overnight as a leak test before throwing the top on it. Note corners cut out of the baffles for anti-sloshing.

Here's a good view of the ledges, ready for micro/flox fillet and the tops to be pressed into place. Also the fuel pickup and low-level fuel switch. The big secret here is to hog out the foam and replace with a 1/4" thick piece of aluminum with appropriate hole and/or threads already tapped.

This aluminum tube was glassed into the top surface of the tank, to be used as a vent to the inside joint between stub and outer wings. You can see the aluminum plate, tapped for the blue AN6 fuel outlet. Level switch never worked. I give up on those! The outside sharp corners were sanded round with the pad sander and 50 grit paper, then layers of 1" and 2" tape overwrapped to add strength to the outside.

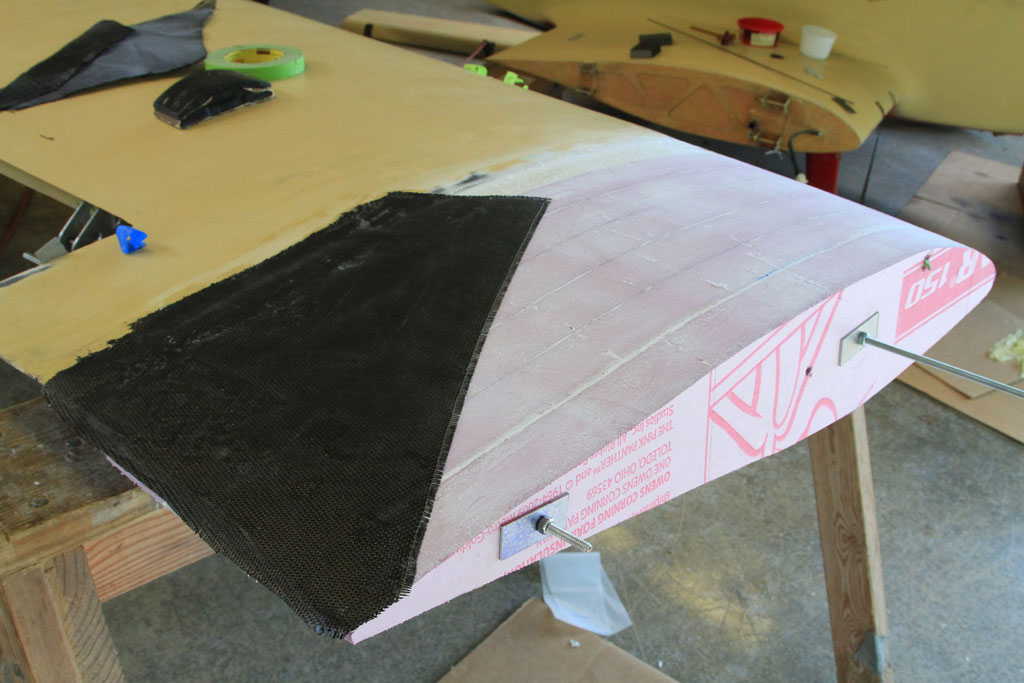

Back when I built my original wingtips, I was in too much of a hurry to spend a few hours and do the research to see exactly what that means. So I sort of

did a Hoerner tip, and then nicely rounded all the edges, which

killed the effectiveness completely, I now know.

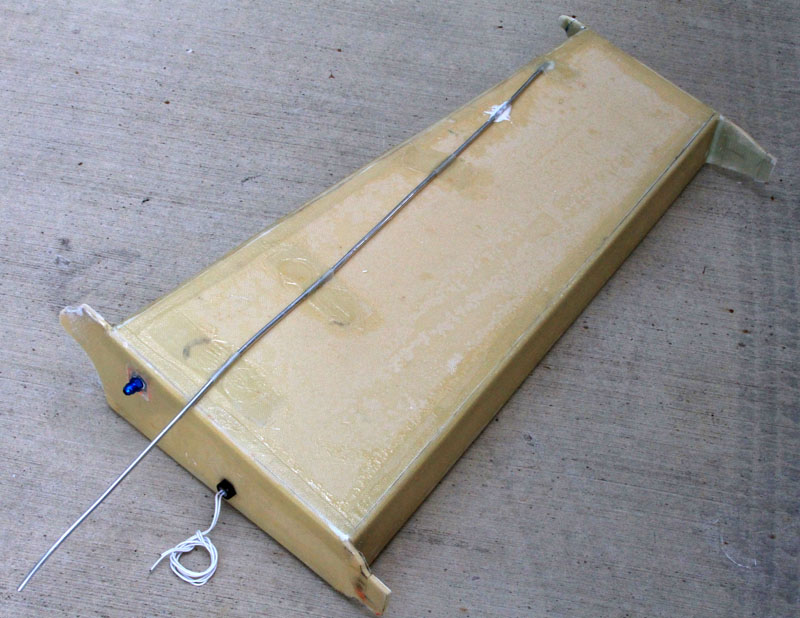

To create a Hoerner tip, glue

a chunk of foam on the end of the wing and contour the top and bottom to

match the adjacent airfoil. Glass it or carbon fiber it, and with a square

end on it (perpendicular to the ground). This is the first tip I made, using styrofoam insulation. I quickly learned to hate this stuff due to the difficulty in sanding, and it's nasty habit of devloping a static charge and sticking to everything nearby.

So on the next one I used a solid chunk of urethane (I still had some left over from my aft deck, but could have done it the plans way out of 1" panels glued in place. In fact, in 20/20 hindsight, that would have given me a perfectly flat end, which would have turned out a lot better than my "hack" job".

Then take a hacksaw or something

similar and starting at either the front or the rear, and using the top edge

of the airfoil cut about a 60 degree angle (measured from vertical) inward

towards the fuselage using the upper "corner" as a guide. Now you know what I mean by "hack job"!

I then carbon fibered it all with two layers of carbon fiber, since the tips are prone to hangar rash and mishandling at airshows.

The usual micro smoothing layer and some finish sanding.

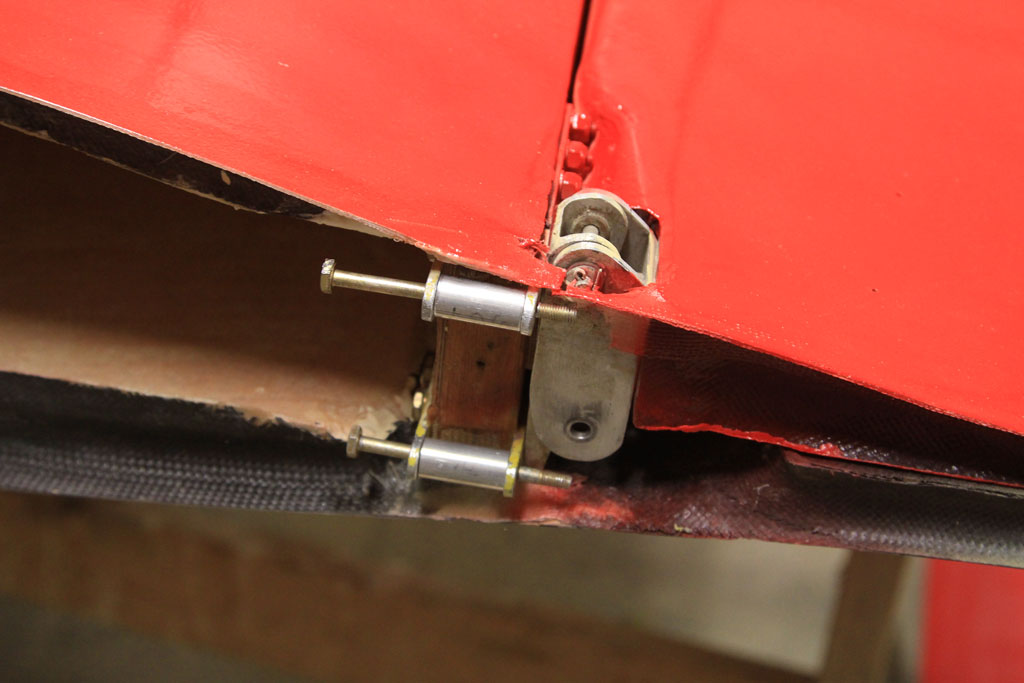

Aluminum spacers were epoxied in place to resist closing the WAFs together when tightening the wing attach bolts.

I made a nutplate plate so I didn't need wrench access to the rear of the fittings. The bolts are socket head, so I only needed a small hole in the stub wing gap to install or remove the WAF bolts.

While I had the wings off, I also added a stub wing gap seal made of two layers of glass tape. You can also see some useless weight on this plane...the wooden end plate, left behind after being used as the airfoi template. I won't make that mistake on my next plane!

Good news folks...I finally painted the bottoms of the wings!

This is how it turned out. Not perfect, but not too bad.

That's a lot of flap angle! And my plane has so much power it will easily climb right out with full flaps extended.

Here's the plane the next day, ready to race the 2010 Airventure Cup Race from Dayton to Oshkosh. Not sure who the family was, but they know how to pick their scenery!

The photo above comes pretty close to telling the whole story of my wing extensions and Hoerner tips. That's what eluded me 10 years ago. Viewed from the top you'd never know it was anything but squared off. The theory is that you can radius the bottom a little, but the top has to be a sharp corner so the air can't turn that sharp corner and turn inward into a vortex, which would be a drag producer. A glide test from 13,000 feet covered 11,050' of altitude in 17.5 minutes (these numbers came off the EIS, so they are exact, not rounded off. The result was a descent rate of 631.4 feet/minute at an average of 87.5 mph, which translates into a 12.1:1 glide ratio. That's better than my previous number of 11.65 feet/minute on the previous wings, done with similar loading. Knowing numbers like these is handy if your engine quits and you need to know which airports you can make it to, and which ones you can't. My test was done with the engine at idle, which I proved several years ago yields the same results as if the engine were switched off. High compression Corvairs with short wooden props don't windmill, at least I've never seen it happen.

Tufting of the new wing versus the old tip showed the flow moving almost parallel to the fuselage, rather than at a 30 degree angle inward like before...a sign that drag is reduced. Wide open throttle tests showed a 1 to 1.5 mph improvement in top speed over the previous wing shape, and this is with a 12% increase in wingspan, so there was a real drag reduction from the Hoerner tips.